March 11, 2025

Tetiana Petruk: Change Management – How Metinvest Adapts to Instability and Staff Shortages

February 20, 2025

The Future of Ukrainian and Italian Metallurgy — One Step Closer. Metinvest and Danieli Reached Signing of Shareholder Agreement for a New Plant in Piombino

December 27, 2024

Metinvest Launches Production of 20 New Products in 2024

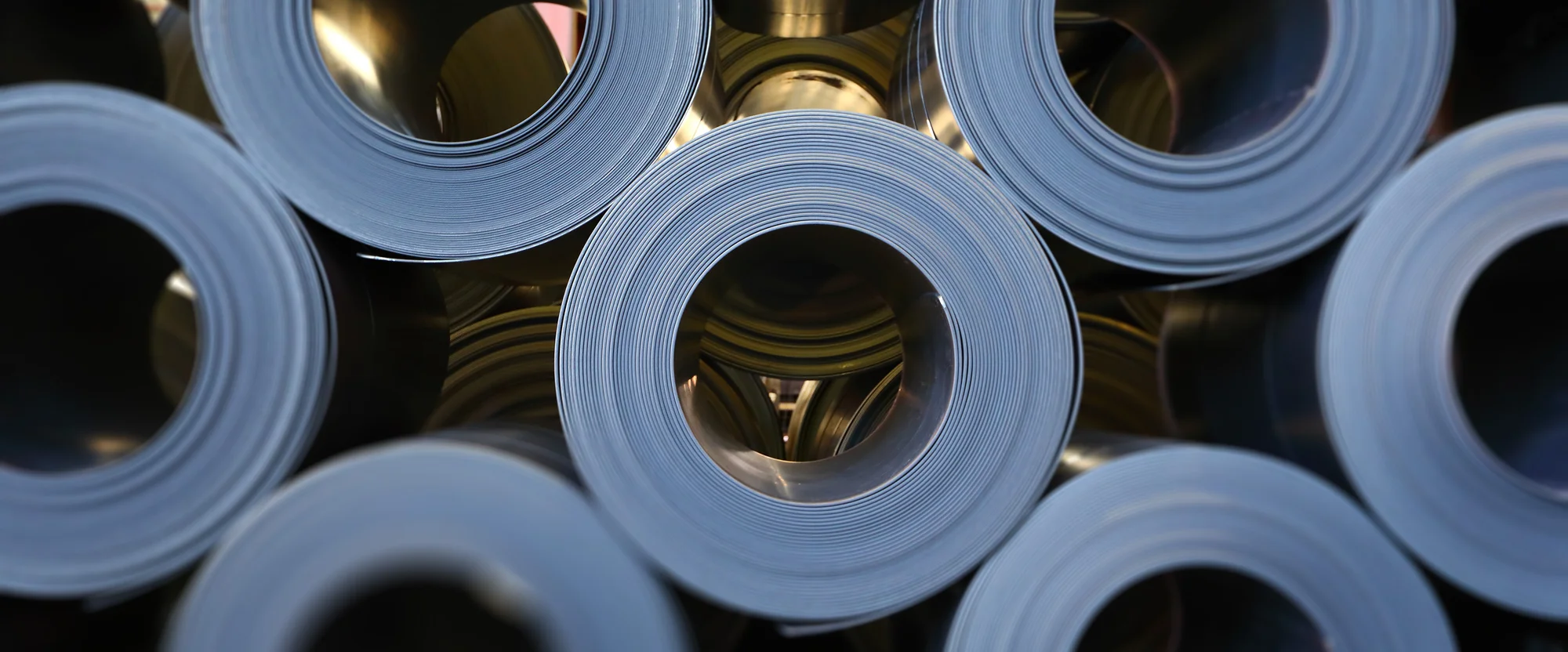

About Us

We supply around 6% of total plate consumption in Italy, 3% of all plate in the EU

Learn more

Certificates

At Ferriera Valsider, quality, safety, and environmental responsibility are at the core of everything we do

Explore

About the team

We are always looking for qualified specialists who can join our team and help us grow together. Learn more about our company and how we work

We are hiring